|

|

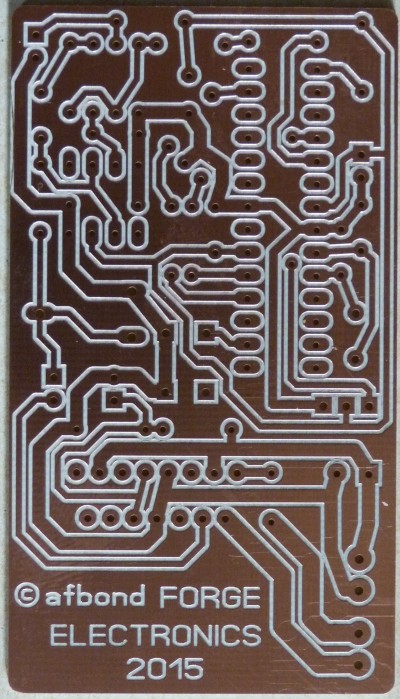

This is a cheap method for low volume production and fast prototyping, a small isolation milled PCB costing just a few pounds whereas a hundred pounds might need to be spent to procure a chemically etched PCB. The latter are best suited to mass production as most of the cost is for masks and tooling and so in volume the per board cost can be much cheaper - ie buy 200 etched PCBs and their cost could be in the tens of pence. Also you have the option to have plated through holes (for double sided PCBs) and a silk screen showing component positions and designations, labelling of connectors, company name/logo etc With isolation milling a PCB design file is supplied to the manufacturer who uses an NC (numerically controlled) milling machine to drill the holes and then, by milling, removes the copper from a sheet of PCB material to create the necessary pads and tracks by milling around their edges to leave the required connection isolated from the copper backplane

6th January 2017 The (UK based) Isolation Milling Service I used is no more. Marek Kuczynski died in the early hours of this morning after several months in hospital, due to complications following major abdominal surgery undergone in October. Over the last couple of years he became far more than just a supplier - wonderful sense of humour and great Dr Who fan - I will miss you my friend.

|